News

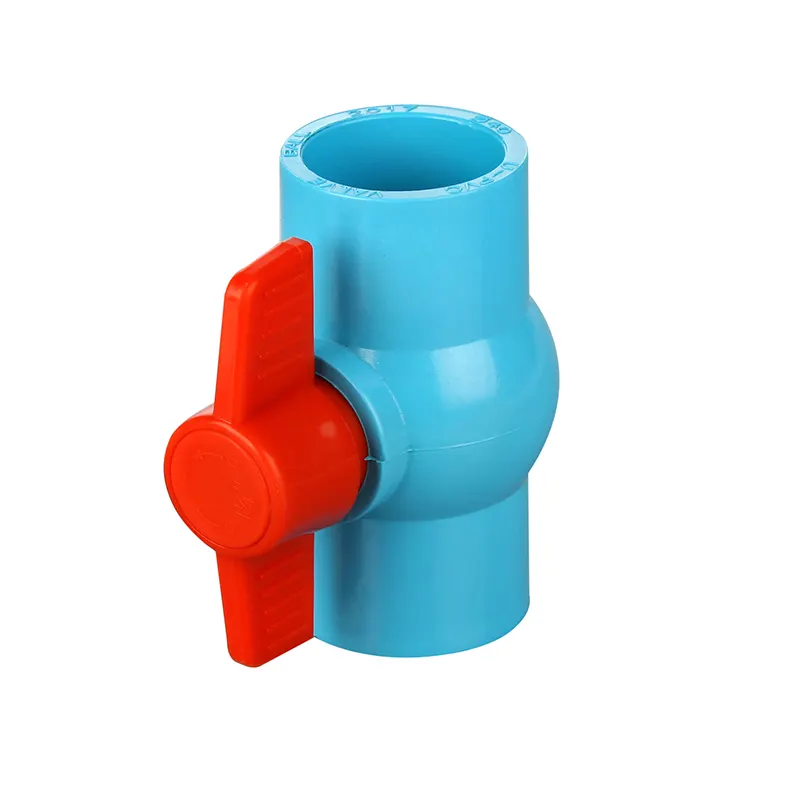

PVC Ball Valve From China Compact Plastic Manual Control Irrigation Ball Valve OEM Supported

About this product,it is made of PVC material,light blue body,red butterfly handle,TIS socket,exported to Thailand.We have these sizes at present,for example 1/2 inch 3/4 inch 1 inch 1-1/4 inch 1-1/2 inch 2 inch.The Warranty period is 2 years.Our product meets international standards, ensuring compatibility with various pipe systems and applications.In addition,we will provide customized services for customers in different countries and regions,including color,size,packing and so on.

PVC ball valves (Polyvinyl Chloride ball valves) are widely used in various fields such as industrial, domestic water supply, and agricultural irrigation. Made from PVC material, PVC ball valves efficiently control the flow of liquids or gases in pipelines, and they are easy to operate. This article will explore the technical features, use cases, and installation & maintenance of PVC ball valves to help you better understand this essential pipeline component.

Technical Features of PVC Ball Valves

-

Strong Corrosion Resistance

One of the key features of PVC ball valves is their excellent corrosion resistance. PVC material is chemically stable and can resist corrosion from most acidic, alkaline, and saline substances. Compared to metal ball valves, PVC ball valves perform exceptionally well in harsh environments, making them widely used in chemical transportation and wastewater treatment. -

Lightweight and Easy Installation

PVC ball valves are much lighter than metal valves, making them easier to handle, transport, and install. In most cases, PVC ball valves can be installed without heavy equipment or special tools. This makes them ideal for situations where valves need to be frequently repaired or replaced, reducing labor and installation costs. -

Excellent Sealing Performance

PVC ball valves are designed with a ball and seat seal that provides superior sealing capabilities, ensuring that the valve does not leak when it is closed. During the opening and closing process, the hole in the ball aligns perfectly with the pipe, ensuring complete fluid flow control or complete shutoff, preventing unnecessary leaks. -

Pressure and Temperature Resistance

PVC ball valves typically have a pressure resistance of 6-10 bar, which is suitable for most pipeline systems. They perform well in temperature ranges of 0-60°C, making them suitable for daily water supply, chemical flow, and warm water systems. While PVC ball valves are not suitable for extremely high-temperature environments, they are more than adequate for typical water piping systems. -

Fluid Control Performance

PVC ball valves use a rotating ball to control the flow of fluid inside the pipe. When the ball rotates, the hole in the ball aligns with the pipe, enabling rapid flow regulation. PVC ball valves have low flow resistance, making them precise in flow control and capable of quickly shutting off fluid flow when needed. Compared to other types of valves, PVC ball valves offer fast and accurate flow control. -

Cost-Effective

The manufacturing cost of PVC ball valves is relatively low, and the material is widely available, making them affordable for mass production. As a result, PVC ball valves are cost-effective, especially in large-scale installations like industrial pipelines and agricultural irrigation systems, where they significantly reduce overall expenses.

Use Cases of PVC Ball Valves

PVC ball valves are commonly used in the following scenarios:

-

Domestic Water Supply Systems

In households, PVC ball valves are typically used to control the flow of hot and cold water in pipes. They are often found in water supply systems, water splitters, and irrigation systems. Due to their low cost and easy installation, they are well-suited for everyday household use. -

Agricultural Irrigation Systems

PVC ball valves are widely used in agricultural irrigation. They regulate the flow of water in irrigation pipelines, ensuring that the crops receive adequate water supply. PVC ball valves are ideal for automatic irrigation systems, offering precise control of water flow and promoting efficient water usage. They are commonly used in field irrigation, greenhouse irrigation, and sprinkler systems. -

Chemical Transport Pipelines

Due to their corrosion resistance, PVC ball valves are highly suitable for chemical transportation. Many chemical industries, wastewater treatment plants, and waste treatment systems rely on PVC ball valves to control fluid flow. The sealing performance and corrosion resistance of PVC ball valves ensure the safe transportation of chemicals, preventing leaks and corrosion issues. -

Water Treatment Industry

The water treatment industry requires valves with high reliability, as controlling fluid flow is crucial in both water sourcing and wastewater processing. PVC ball valves are widely used in water treatment plants, water supply systems, and sewage treatment facilities. Their corrosion resistance and wear resistance make them ideal for long-term, high-frequency use in water treatment systems. -

Aquarium and Swimming Pool Systems

PVC ball valves are used in water circulation systems for aquariums and swimming pools. They control the flow of water and regulate the operation of filtration systems. PVC ball valves are easy to operate and can quickly adjust water flow, helping maintain the stability of the water treatment system. Furthermore, their corrosion resistance ensures durability when in constant contact with water. -

Food and Beverage Industry

PVC ball valves can also be used in the food and beverage industry for fluid control, especially in pipelines carrying drinking water, fruit juices, and other liquids. Since PVC is non-toxic and odorless, it ensures the purity and safety of the fluids during processing and transportation.

Installation and Maintenance of PVC Ball Valves

Installation Steps:

- Shut off the Water Supply: Before installing a PVC ball valve, turn off the water supply in the system to ensure that no fluid is flowing through the pipe.

- Select the Appropriate Size: Choose a PVC ball valve with the correct size based on the pipe diameter and working pressure. Using the wrong size can lead to poor sealing or difficulty in installation.

- Cut the Pipe: Use appropriate tools to cut the pipe to the required length. Make sure the cut is clean and smooth to ensure a tight seal when connecting the valve.

- Use PVC Glue for Connection: PVC ball valves are typically connected to pipes using PVC glue. Apply the glue evenly to the pipe and valve ends before fitting them together. Ensure a tight connection for leak-proof performance.

- Check Flow Direction: PVC ball valves usually have an arrow indicating the direction of fluid flow. Make sure to install the valve in the correct orientation.

- Secure the Valve: After installation, check that the valve is securely fixed and ensure the pipe is not leaking.

Maintenance of PVC Ball Valves:

- Regular Inspection: Periodically check the ball valve for cracks, damage, or signs of wear. If the sealing ring is worn or damaged, replace it promptly.

- Cleaning and Lubrication: Keep the valve clean and free from debris that could interfere with its operation. If the valve becomes stiff to operate, apply a small amount of lubricant to ensure smooth movement.

- Check for Leaks: Regularly inspect the valve to ensure that it is not leaking. If there are any leaks, it may indicate that the sealing ring is aging or damaged, and replacement is necessary.

Conclusion

PVC ball valves are versatile, cost-effective, and reliable components for controlling the flow of fluids in various pipeline systems. Their excellent corrosion resistance, ease of installation, and low maintenance requirements make them ideal for a wide range of applications, from domestic water supply to industrial chemical transportation. Understanding the technical features, common use cases, and installation & maintenance practices of PVC ball valves will help you make informed decisions when selecting and using them in your systems.