Správy

Nová voľba pre potrubkové sústavy na Blízkom východe: Komplexná analýza výkonnosti prídavných kusov PPA

V Blízkom východe, kde prevádzajú extrémne environmentálne podmienky, je spoľahlivosť potrubkových systémov kľúčová. Vysoké teploty, intenzívna UV žiarenie a písečné búrky predstavujú významné výzvy, zatiaľ čo priemyselné odvetvia ako ropa, plyn a chemikálie vyžadujú odolnosť proti korozií a materiály s vysokou pevnosťou. Tradičné potrubkové materiály často nemôžu tieto výzvy splniť. Avšak, PPA PRÍPOJKY (Fitingy z polyftalamidu) sa prejavujú ako nové riešenie,ďakoviac svojmu vynikajúcemu výkonu. V tomto článku si ukážeme, ako sa PPA fittingy vyjasňujú na blízkomvýchodnom trhu a analyzujeme ich mocné vlastnosti.

Čo sú PPA Fitingy?

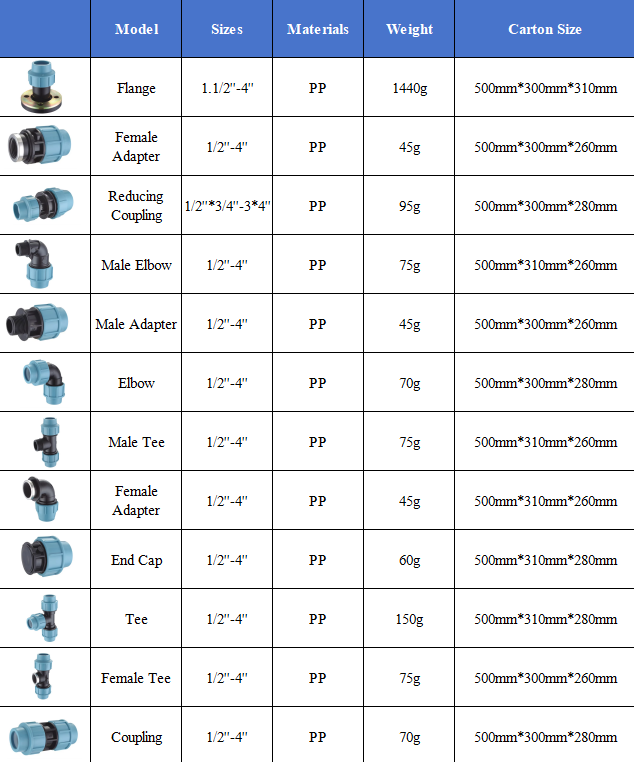

PPA fittingy sú komponenty vyrobené z Polyphthalamide (PPA) , vysoko výkonný plast, známy svojou vynikajúcou odolnosťou predčasnému stareniu pri vysokých teplotách, korozií, UV ochranou a sily. PPA prilby sú ideálne na použitie v priemysle so značnými požiadavkami, ako je ropy a plyn, chemický priemysel, výroba elektriny a očistenie vody. Na trhu na Blízkom východe sa stali predvoľbou kvôli ich vyššej prispôsobivosti. Toto sú informácie o niektorých z našich potrubných priliekov exportovaných do regiónu Blízkeho východu.

Prečo sú PPA prilby ideálne pre trh na Blízkom východe?

Životné podmienky na Blízkom východe sú extrémne náročné. Vysoké teploty, intenzívna UV žiarenia a písečné búrky, spojené s konkrétnymi požiadavkami ropného, plynového a chemického priemyslu, robia ťažké pre tradičné materiály, aby tieto výzvy prekonali. Avšak, PPA prilby ponúkajú nasledujúce silné vlastnosti, ktoré ich vyjadňujú:

1. Odolnosť predčasnému stareniu pri vysokých teplotách, spolehlivá prevádzka

Teploty na Blízkom východe často presahujú 50°C v lete a niektoré pouštné oblasti udržiávajú teploty vyššie ako 40°C po celý rok. V takom extrémnom vedle môžu konvenčné plastové spoje deformovať, degenerovať alebo prasknúť. PPA spoje však vydržiavajú teploty až 150°C , čo zabezpečuje spolehlivú a stabilnú funkciu aj v extrémnom vedle. Či už v ropyľaftých poliach Saúdskej Arábie alebo v priemyselných zónach Zjednotených arabských emirátov, PPA spoje zabezpečujú, aby systémy potrubí fungovali efektívne a spolehlivo.

2. Odolnosť pred koroziou, predĺžená životnosť

Potrubia v priemyselných odvetviach ako je ropa, plyn, chemikalie a očistenie vody často prepravujú korozióne látky, ako sú kyseliny, lúhy, oleje a plyny. Tradičné kovové alebo plastové potrubia môžu ľahko utrpieť koroziu. PPA spoje však ponúkajú vynikajúcu odolnosť pred koroziou, sú 3 krát odolnejšie ako PVC spoje a 5 krát odolnejšie proti konvenčným kovovým spojiskám. To spravuje PPA spojiská ideálnou voľbou pre ropné a plynové potrubia na Blízkom východe, čo zníži náklady spojené s poškodením spôsobeným koróziou a predĺží životnosť potrubí.

3. Odolnosť proti UV záporu, dlhodobá odolnosť

S intenzívnym slnečným svetlom a dlhodobým vystavením UV záporu na Blízkom východe sú konvenčné plastové spojiská predísložene podliehane praskaniu a starnutiu kvôli UV záporu. PPA spojiská však majú vysokú odolnosť proti UV záporu, čo zabráni degradácii spôsobenej dlhodobým vystavením slnečnému svetlu. Štúdie ukázali, že PPA spojiská sú 2 krát odolnejšie proti poškodeniu spôsobenému UV záporom ako štandardné plastové spojiská. Táto charakteristika robí PPA spojiská vysoce efektívnymi v projektoch, ktoré sú vystavené slnečnému svetlu počas dlhších obdobia, čo zníži riziko poškodenia spôsobeného UV záporom.

4. Ľahké a odolné, zníženie nákladov na dopravu a inštaláciu

V porovnaní s tradičnými kovovými spojiskami sú PPA spojiská 40% ľahšie . Toto nie len zníži náklady na dopravu, ale tiež zrýchli inštaláciu. V veľkých projektoch môže použitie spojiek PPA významne skrátiť čas inštalácie, čím sa znížia celkové náklady na projekt. Napríklad veľký projekt v Dubaji sa podarilo urychliť o 30%po použití spojiek PPA, čo zvýšilo celkovú efektivitu projektu.

Aplikácie spojiek PPA

Ďakujúc ich jedinečným výhodám sú spojky PPA široko používané v rôznych odvetviach na Blízkom východe, osobitne v nasledujúcich sektoroch:

- Nefárny a plynársky priemysel : Spojky PPA môžu spolehlivo fungovať v extrémnych teplotách a s korozivnými kaplami, čo ich robí ideálnymi pre prepravu ropy a plynu a systémy potrubí.

- Chemický priemysel : Chemické továrne vyžadujú systémy potrubí, ktoré odolávajú kyselínám, lizinkám a iným korozivným látkám. Spojky PPA sú ideálnou voľbou kvôli svojej vynikajúcej odolnosti pred koreziami.

- Úprava vody : Spojky PPA zabezpečujú dlhodobú stabilitu systémov potrubí v procesoch čistenia vody, čím sa zníži potreba údržby.

- Stavba a infraštruktúra : Lehké a trvanlivé vlastnosti PPA spojoviek ich robí cennými v projektoch stavby a infraštruktúry, čo pomáha znížiť náklady na inštaláciu a zlepšiť stabilitu systému.

Budúci výhľad

Keď sa industrializácia na Blízkom východe pokračuje, osobitne v odvetviach ako nafty a plyn, chemikálií a stavebnictva, poptanie po materiáloch na vysokovýkonné potrubia bude ďalej rásť. S ich vynikajúcimi vlastnosťami odolnosti proti vysokým teplám, korozií, ochrany pred UV záporom a trvanlivosťou sa očakáva, že PPA spoje budú dominovať na trhu s potrubiami na Blízkom východe v nasledujúcich rokoch, hraničiacovi stále dôležitejšiu úlohu v priemysle potrubných systémov.

Záver

Prilby PPA sa stali ideálnou voľbou pre potrubníkové systémy na Blízkom východe dank ich vynikajúcej výkonnosti. Či už je to odolnosť voči extrémnym teplotám, odolnosť voči korozií, ochrana pred UV záporom alebo ich lehkosť a trvanlivosť, prilby PPA vynikajú poskytovaním spolehlivých a ekonomických riešení. Keď sa vzrástajúca požiadavka na vysoko výkonné potrubníkové riešenia na Blízkom východe nadále zvyšuje, prilby PPA sú pripravené zohrať ešte dôležitejšiu úlohu v tejto oblasti, stávajúc sa kameňom moderných potrubníkových systémov.